Along with flying development of electronic industry, the volume of electronic product is getting smaller and smaller while power density larger and larger. Heat dissipation has turned into a much important matter. This is a huge challenge to electronic industry design. Aluminum base copper-clad laminate is undoubtedly oneof the effective means to settlement of this problem.

The Aluminum base copper-clad laminate is a unique metal-base copper-clad substrate with advanced dielectric properties, enhanced thermal conductivity and excellent mechanical performance. The heat caused by power devices is transferred efficiently step by step. Firstly, from circuit layer to dielectric layer, then to metal base layer, then to heat sink.

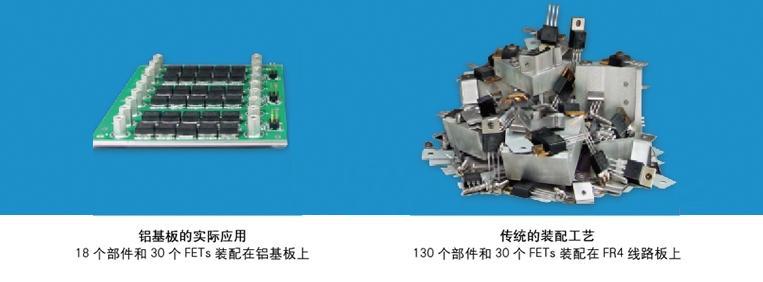

When comparing with conventional FR-4, the Aluminum base copper-clad laminate has lower thermal impedance and higher thermal conductivity. Meanwhile, it has much more excellent mechanical performance when comparing with Ceramic boards. Its benefits include:

- RoHS compliant

- Effectively manage heat dissipation treatment in circuit board design

- Reduce operation temperature, increase power density and reliability and extend service life;

- Reduce heat sinks and other mounting hardware, including thermal interface material

- Replace fragile ceramic substrates with greater mechanical durability

■ Circuit layer

In general, copper foil is etched to form printed circuit with each component interconnected. With the same line width and thickness, IMS boards can carry much more current. Normally, the thickness of copper foil from 1~4OZ (35μm~140μm) are available.

■ Dielectric layer

The technology of Thermal Clad resides in the dielectric layer. The dielectric is a proprietary polymer/ceramic blend that gives Thermal Clad its excellent electrical isolation properties, low thermal impedance and also withstands mechanical and thermal stress. The polymer is chosen for its electrical isolation properties, ability to resist thermal aging and high bond strengths. The ceramic filler enhances thermal conductivity and maintains high dielectric strength.

Our product LED-0602 is designed specially for power LED. The dielectric layer comes from Bergquist Company and its conductivity can come up to 1.1 W/m·K. By the way, it has gained UL certification at the temperature of 130℃. This is really tough. Actually, it performs rather reliably and has won great fame in the field of high power LED.

While other manufacturers use standard prepreg as the dielectric layer, but prepreg doesn’t provide the high thermal conductivity and the thermal conductivity is just only 0.3W/m·K .The thermal conductivity is very poor and the breakdown voltage is too limited to satisfy the safety agency test requirements(≤2KV AC). Actually, it’s hard for those products to qualify the need of high power LED or high watt-density situation.

■ Metal base layer

This is a structure to support aluminum base copper-clad laminate and required to have high thermal conductivity. Usually it is aluminum, while copper may also be used, suitable for regular mechanical process, such as drilling, punch and cutting, etc.

|